| Part No.: | 1-431-07-00 |

Part No.:

1-431-07-00

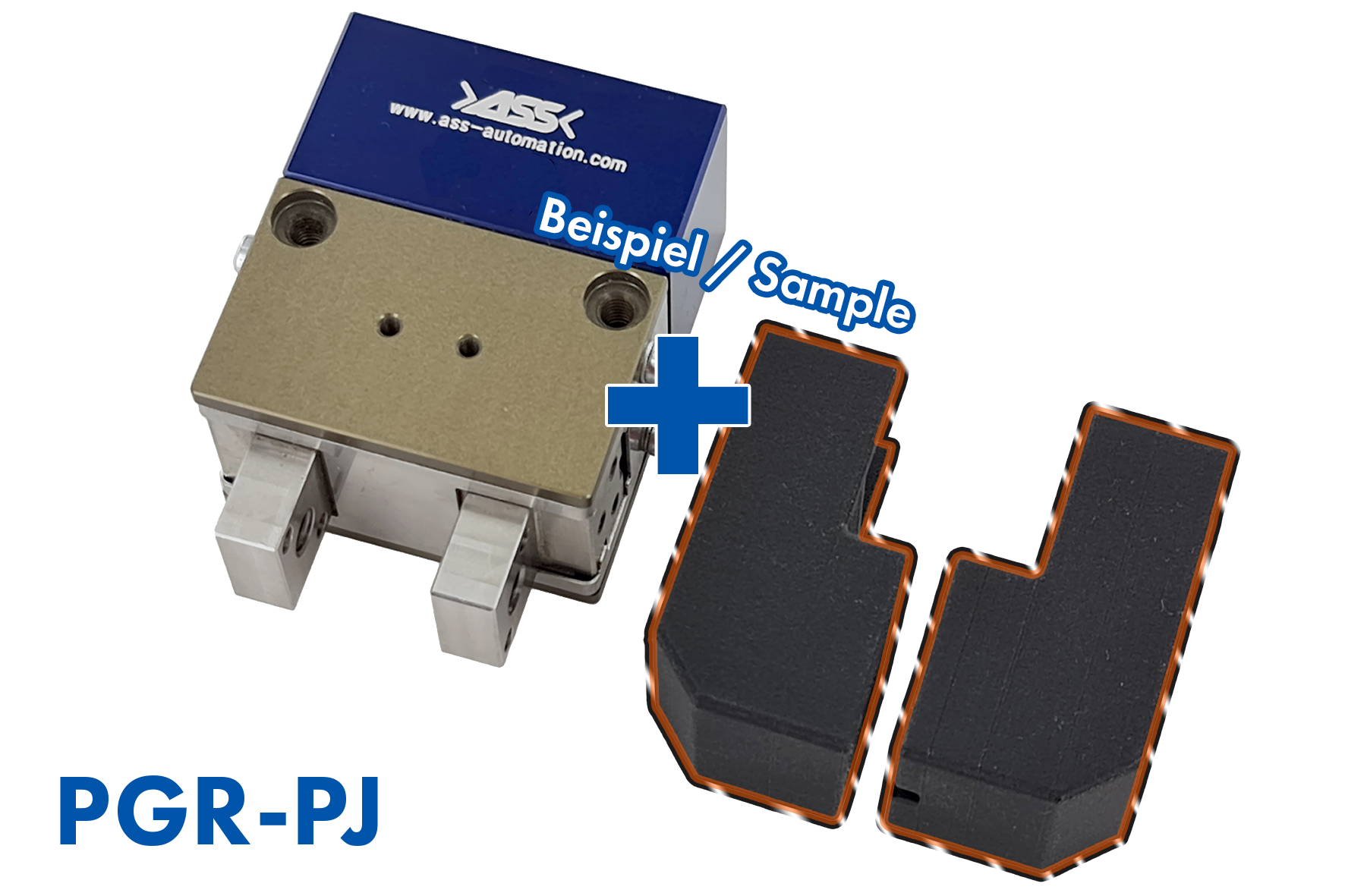

Fixed costs for grippers and jaws:

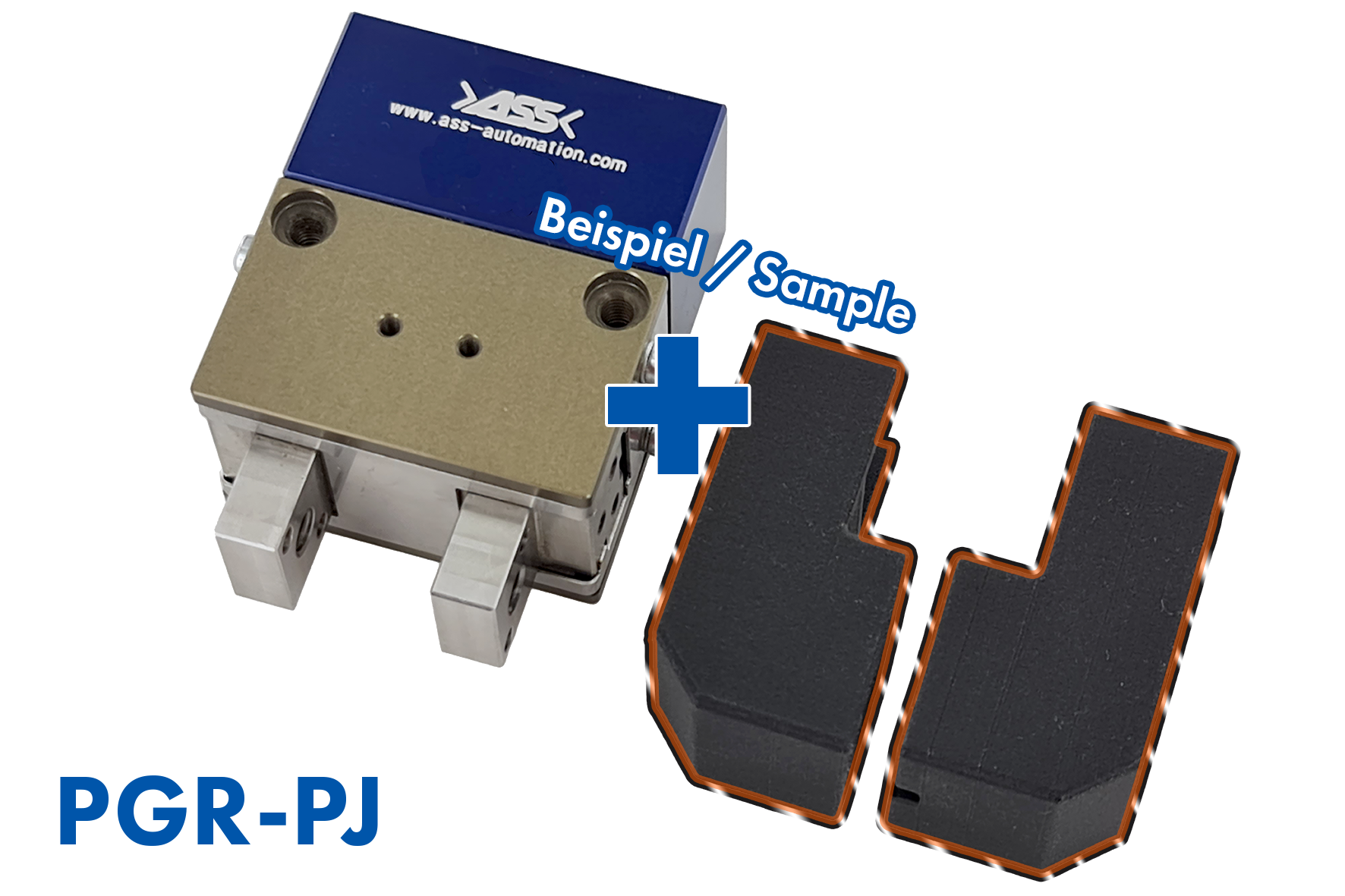

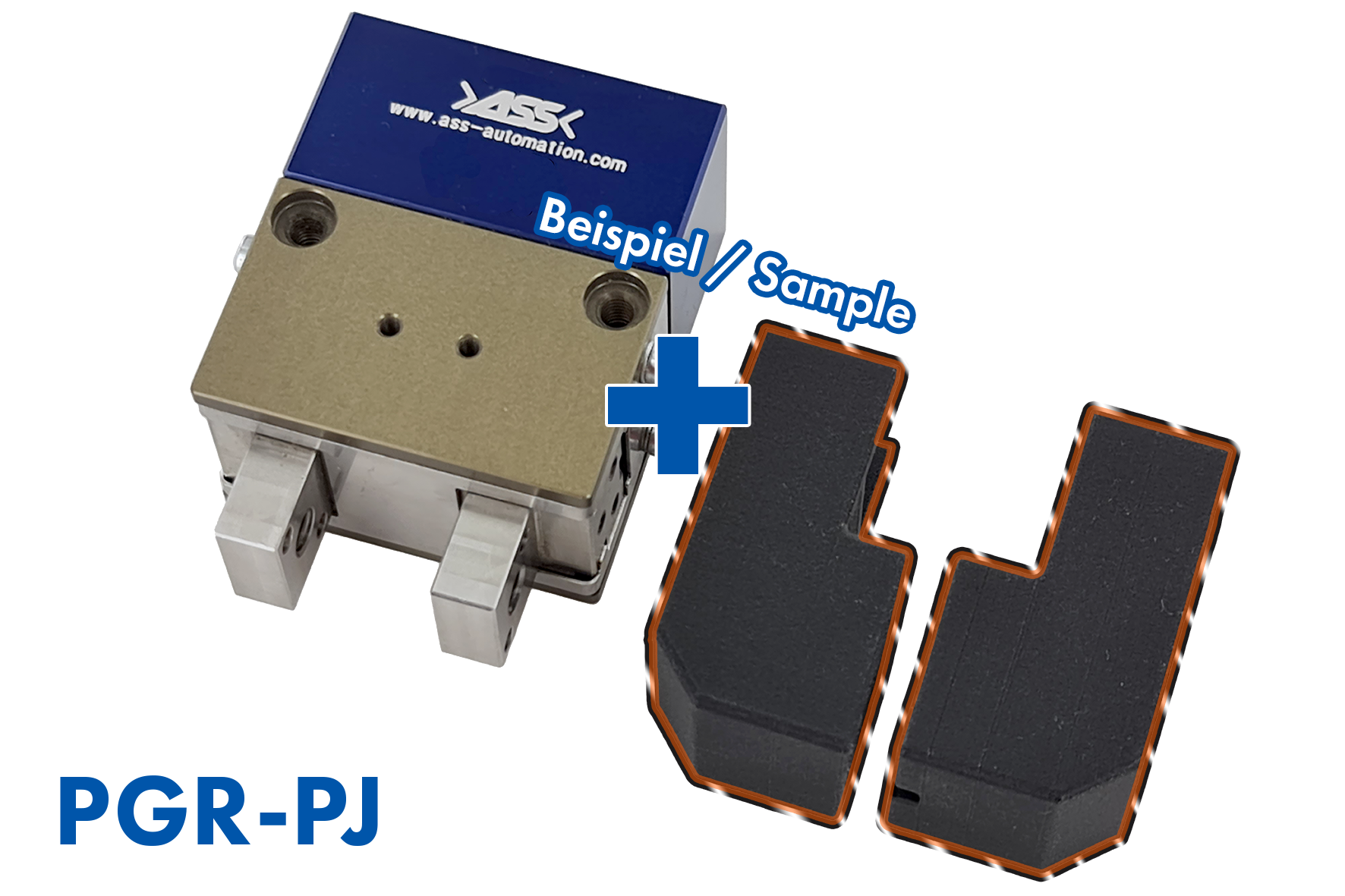

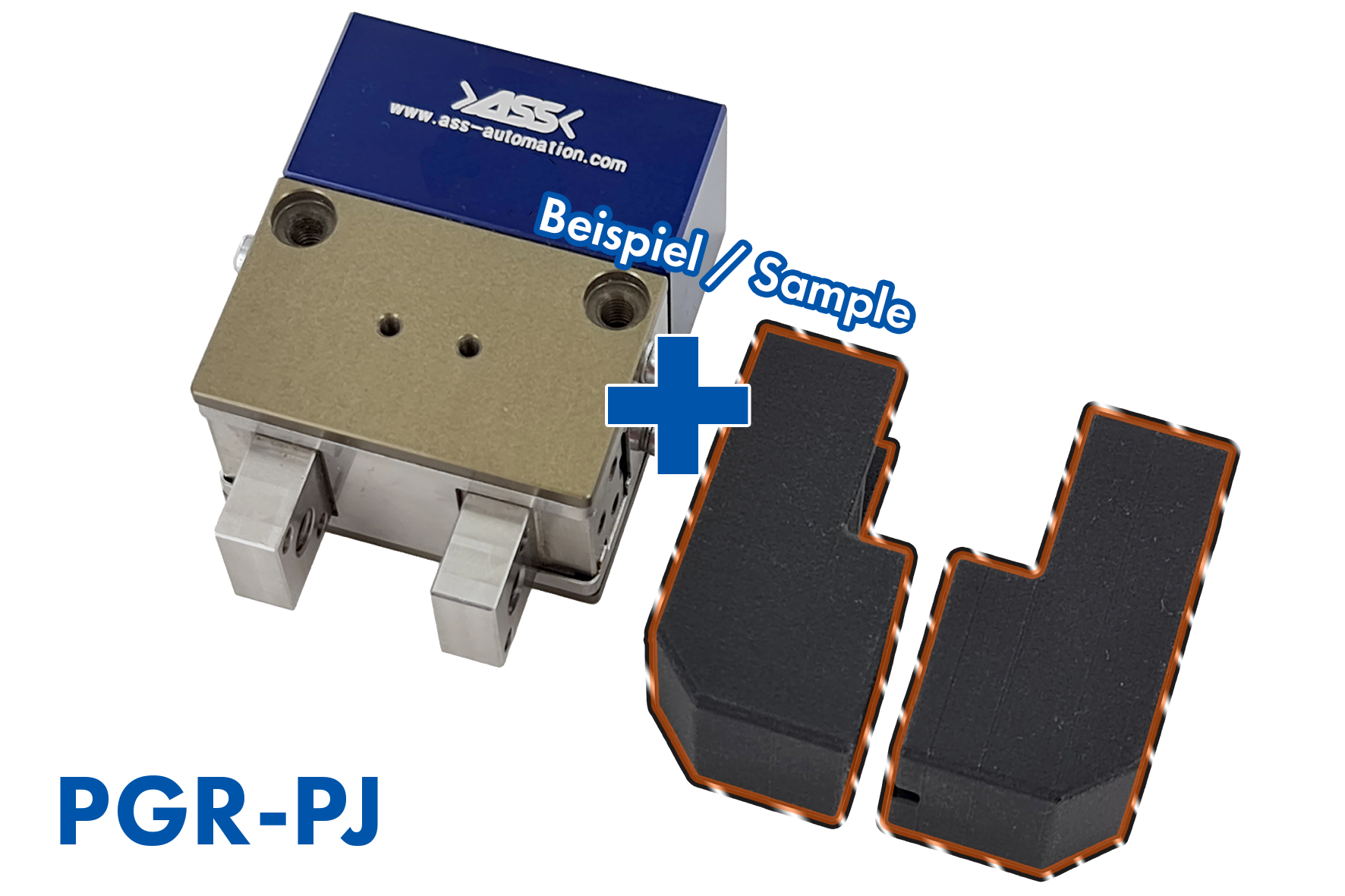

A fixed price for each size for our parallel grippers including 3D printed jaws, that is the PGR-PJ.

Design freedom:

Precise design of the jaws on the parts to be gripped. All we need is the component data and we will take care of the component-specific creation in the specified installation space.

The pair of jaws is designed as a negative of your component. You determine the gripping area.

For special gripping situations, tool requirements or clearances, we need your design data.

Other dimensions or installation space studies are of course possible on request.

Top quality:

A fixed price for each size for our parallel grippers including 3D printed jaws, that is the PGR-PJ.

Design freedom:

Precise design of the jaws on the parts to be gripped. All we need is the component data and we will take care of the component-specific creation in the specified installation space.

The pair of jaws is designed as a negative of your component. You determine the gripping area.

For special gripping situations, tool requirements or clearances, we need your design data.

Other dimensions or installation space studies are of course possible on request.

Top quality:

The

3D printed jaws are made of a high-strength and durable onyx material,

also reinforced with continuous fibers if necessary. These then cover

all applications of conventional jaws milled from aluminum.

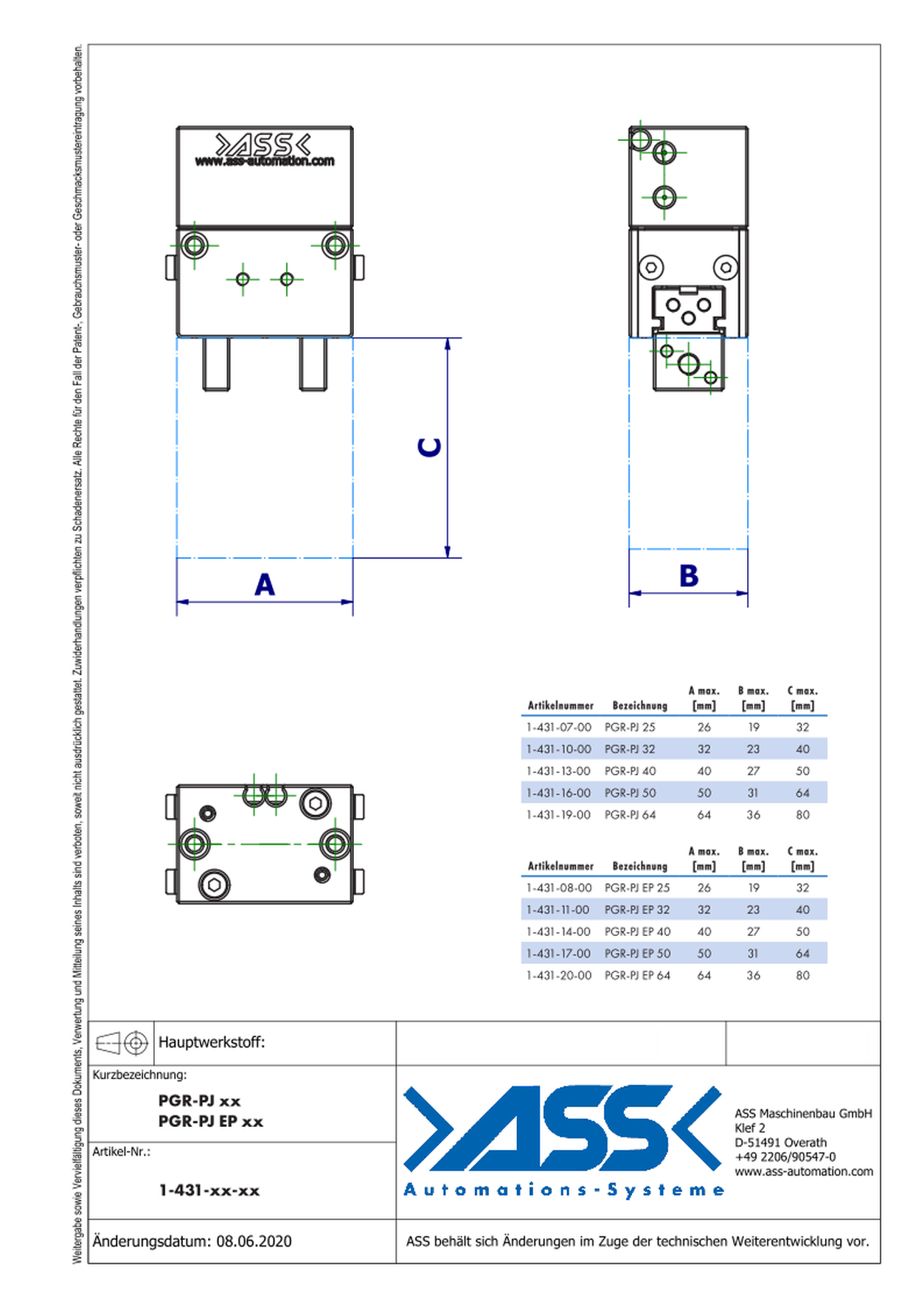

- the stated weight only refers to the parallel gripper without gripper jaws

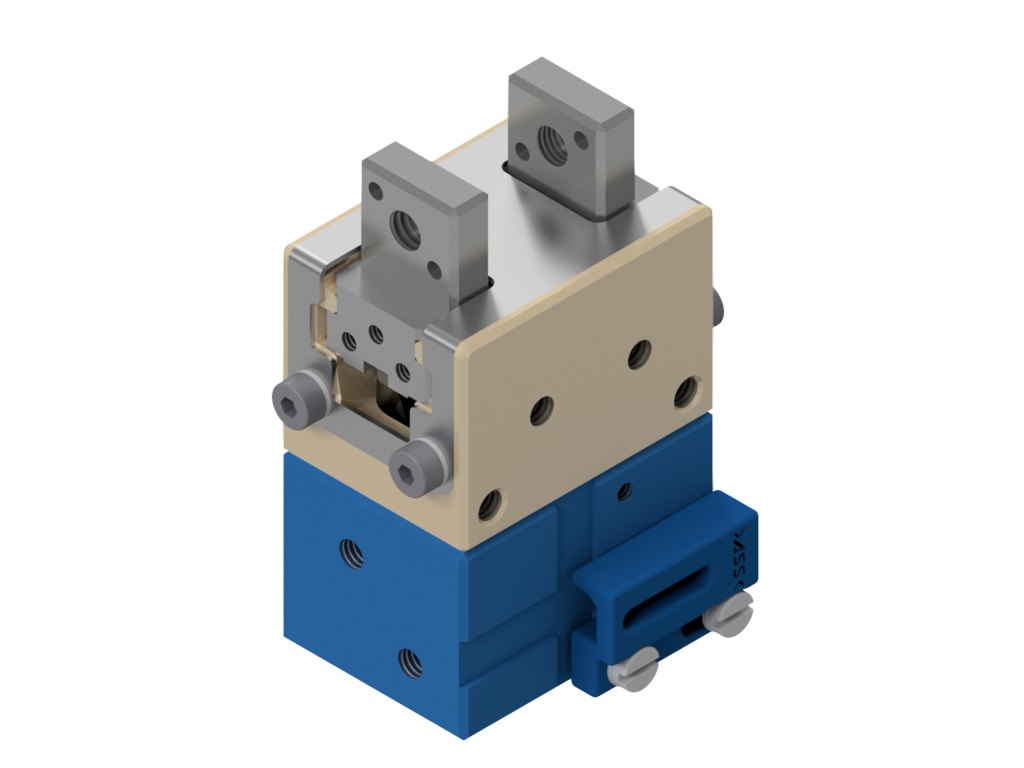

- rendered image and data sheet serve as a general example for the product group

- the product photo shows the respective PGR-P which serves as the basis for the product

- e.g. for precise gripping or inserting applications

- load-bearing and low-play T-slot guide for safe and precise handling with high load ratings

- drive concept for maximum gripping force

- housing made of high-strength aluminum alloy for minimum weight and high stiffness

- double acting: can be used as as external or internal gripper

- small construction volume for minimal contours

- centering possibilities on the gripping jaws

- versatile adaptations for flexible assembling

- power supply on two gripper sides possible; also hoseless direct connection possible

- integrated permanent magnet for sensing end position (see accessories)

- precise sensing of jaw position by adapting induction field sensors (see accessories)

- maximum air pressure is 6 bar, use dry and filtered air only

- AP PGR - adaptation of the parallel gripper to the respective extension tube

- MFS T2 - magnetic field sensor with 2 switching points „teachable“ for the end position sensing of the piston rod, easy to mount via the integrated C-slots (Part No. 1-808-30-00)

- ICS 8 - 3-pole magnetic field sensor for end position sensing of the piston rod, easy to install via the integrated C-slots, basic and working position requires one sensor each

(Part No. 1-808-36-00) - IRK 4 - induction field sensors for the end position detection of the gripper jaws, basic and working position requires one sensor each, sensor bracket in the scope of delivery (Part No. 1-808-02-00)

- AS-P PGR-P - Sensor Bracket Precise mounting kit: complete set for querying the exact jaw position using induction field sensors

| Active principle: | double-acting |

|---|---|

| Hose connection: | 3/0,5 mm |

| Hose connection thread: | M3 |

| Jaw material: | stainless Steel |

| Material: | Aluminium |

| Monitoring: | optional |

| Stroke per Jaw: | 3 mm |

| Weight: | 60 g |

Downloads and 3D-data are only available to logged in users.